Vertical Shaft Impact Crusher Design

Posted: 2025-03-14 Source: Liming Heavy Industry Views: 240

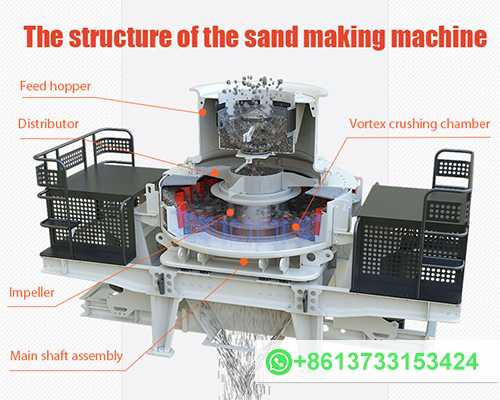

Introduction to Vertical Shaft Impact Crusher

A vertical shaft impact (VSI) crusher is a specialized machine designed to crush hard materials into high-quality, cubical aggregates. Unlike traditional crusher, VSI crusher use a high-speed rotor and anvils to propel materials against each other, achieving precise particle shaping and size reduction. This design is widely used in mining, quarrying, and recycling industries for producing premium-grade sand, gravel, and industrial minerals.

In this article, we break down the core components of VSI crusher design, its operational benefits, and best practices for maximizing efficiency.

Key Design Features of Vertical Shaft Impact Crusher

- Rotor Assembly

- The heart of the VSI crusher, the rotor spins at high velocities (up to 80 m/s) to hurl materials against the crushing chamber.

- Types: Open rotor, closed rotor, or hybrid designs for balancing wear and energy efficiency.

- Crushing Chamber

- Configured with rock-on-rock or rock-on-anvil setups:

- Rock-on-Rock: Materials collide with each other, ideal for abrasive minerals.

- Rock-on-Anvil: Materials strike stationary anvils, suited for softer rocks.

- Configured with rock-on-rock or rock-on-anvil setups:

- Feed System

- A central feed tube directs materials into the rotor, ensuring even distribution and minimizing blockages.

- Drive System

- Electric or diesel engines paired with belts or direct drives for adjustable speed control.

- Adjustable Cascade Flow

- Allows operators to regulate material flow through the rotor, optimizing particle shape and gradation.

Advantages of VSI Crusher Design

- Superior Particle Shape

- Produces cubical, well-graded aggregates ideal for concrete, asphalt, and road base.

- High Reduction Ratios

- Achieves up to 30:1 size reduction in a single pass, reducing the need for secondary crushing.

- Low Operating Costs

- Minimal wear parts (e.g., rotor tips, anvils) and energy-efficient operation lower long-term expenses.

- Versatility

- Handles diverse materials, from granite and basalt to recycled concrete and glass.

- Automation Compatibility

- Modern VSI crusher integrate with IoT sensors for real-time monitoring of performance metrics.

Applications of Vertical Shaft Impact Crusher

- Manufactured Sand Production

- Creates high-quality artificial sand for construction, replacing natural sand in concrete mixes.

- Mineral Processing

- Refines ores like iron, copper, and gold into uniform particles for downstream processing.

- Recycling

- Crushes demolition waste (concrete, bricks) into reusable aggregates.

- Glass and Ceramic Industries

- Produces finely crushed materials for specialized industrial uses.

Design Considerations for Optimal Performance

- Material Hardness: Choose rotor tips and anvils made from tungsten carbide for abrasive materials.

- Feed Size: Ensure feed particles are within the crusher’s capacity (typically ≤50 mm).

- Moisture Content: Avoid clogging by pre-screening overly wet or sticky materials.

- Maintenance Access: Opt for designs with easy-to-remove wear parts for quick replacements.

Comparing VSI Crusher to Horizontal Shaft Impact (HSI) Crusher

| Feature | VSI Crusher | HSI Crusher |

|---|---|---|

| Particle Shape | Cubical, uniform | Angular, less uniform |

| Wear Costs | Lower (fewer wear parts) | Higher (hammers, blow bars) |

| Applications | Sand production, fine crushing | Primary/secondary crushing |

| Energy Use | Higher speed, moderate energy | Lower speed, higher energy |

Maintenance Tips for VSI Crusher

- Regular Rotor Inspection

- Check for imbalance or wear on rotor tips and replace them in sets.

- Lubrication Schedule

- Maintain bearings and gears with manufacturer-recommended lubricants.

- Monitor Vibration Levels

- Excessive vibration may indicate misalignment or rotor damage.

- Update Software

- For automated systems, ensure firmware is up-to-date for peak efficiency.

Choosing the Right VSI Crusher Design

- For High Abrasion: Opt for rock-on-rock configurations with open rotors.

- For Precision Grading: Select models with adjustable cascading flow controls.

- For Mobility: Consider portable VSI crusher for on-site projects.

Conclusion

Vertical shaft impact crusher design revolutionizes aggregate production by combining precision engineering with operational efficiency. Its ability to produce perfectly shaped particles, reduce costs, and handle diverse materials makes it indispensable in modern mining and construction. By understanding its design principles and maintenance needs, businesses can unlock higher productivity and ROI.