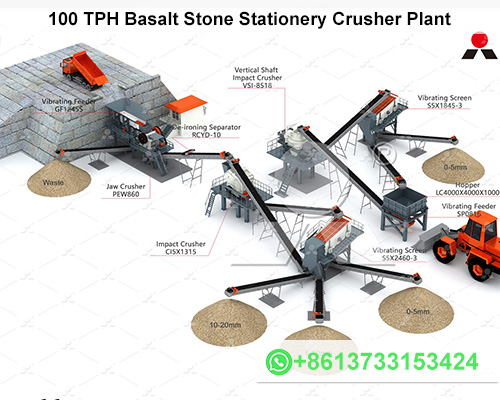

100 TPH Basalt Stone Stationery Crusher Plant in Somalia

- High Demand for Aggregates

Somalia’s infrastructure revival, including roads, ports, and housing, requires durable basalt aggregates. A stationary plant ensures consistent supply for large-scale projects. - Adaptability to Harsh Conditions

Stationary crusher is designed for long-term operations, ideal for Somalia’s rugged terrain and extreme weather. - Cost Efficiency

Producing aggregates on-site reduces transportation costs and delays, critical in remote regions. - Job Creation

Local employment opportunities in plant operation and maintenance support community development. - Primary Jaw Crusher

- Crushes raw basalt (≤600 mm) into 150–200 mm chunks.

- Recommended: PE-600×900 Jaw Crusher (75 kW motor).

- Secondary Cone Crusher

- Further reduces material to 20–50 mm for versatile applications.

- Example: PYB1200 Cone Crusher (110 kW motor).

- Vibrating Screens

- Classifies aggregates into sizes (e.g., 0–5 mm, 5–20 mm, 20–40 mm).

- 3-deck screens optimize output for concrete, asphalt, or drainage layers.

- Conveyor Belts and Feeders

- Ensures smooth material flow between crusher and screens.

- Dust Control System

- Mitigates airborne particles, complying with environmental standards.

- Road Construction

- Basalt aggregates provide strength for asphalt and road base layers.

- Concrete Production

- Crushed basalt enhances durability in residential and commercial buildings.

- Port and Airport Development

- Used in runways, docks, and erosion-resistant structures.

- Water Drainage Systems

- Sized aggregates improve filtration and flood prevention.

- Equipment Costs

- Primary Crusher: 25,000–25,000–25,000–40,000

- Secondary Crusher: 30,000–30,000–30,000–50,000

- Screens and Conveyors: 20,000–20,000–20,000–35,000

- Total Setup: 150,000–150,000–150,000–250,000 (depending on automation and brand).

- Operational Costs

- Power Consumption: ~150 kWh, requiring reliable electricity or diesel generators.

- Labor: 5–8 skilled workers for 24/7 shifts.

- Tips to Reduce Expenses

- Source equipment from trusted Chinese manufacturers for budget-friendly options.

- Partner with local logistics companies to cut import taxes and shipping costs.

- Opt for modular designs for easier maintenance and part replacements.

- Power Supply Issues

- Solution: Install diesel generators or hybrid power systems.

- Dust and Heat Management

- Solution: Use water spray systems and heat-resistant lubricants.

- Skilled Labor Shortage

- Solution: Collaborate with vocational training institutes for operator programs.

- 30% cost savings compared to imported materials.

- Created 12 local jobs in maintenance and logistics.

Introduction

A 100 TPH (tons per hour) basalt stone stationary crusher plant is a critical investment for infrastructure development in Somalia. With the country’s growing demand for road construction, building materials, and industrial projects, this setup offers a reliable solution to process hard basalt rock into high-quality aggregates.

This guide covers the benefits, key components, applications, and cost considerations of installing a stationary crusher plant in Somalia to meet local and regional construction needs.

Why Choose a 100 TPH Basalt Crusher Plant in Somalia?

Key Components of a 100 TPH Stationary Crusher Plant

Applications of Basalt Aggregates in Somalia

Cost Breakdown and Investment Tips

Challenges and Solutions in Somalia

Case Study: Successful Crusher Plant in Mogadishu

A 100 TPH stationary plant installed in 2022 now produces 2,400 tons of basalt daily, supplying aggregates for the Mogadishu-Afgoye Highway. Key outcomes:

Conclusion

A 100 TPH basalt stone stationary crusher plant is a strategic asset for Somalia’s infrastructure growth. By selecting robust equipment, optimizing operational workflows, and addressing local challenges, businesses can achieve long-term profitability while contributing to national development.