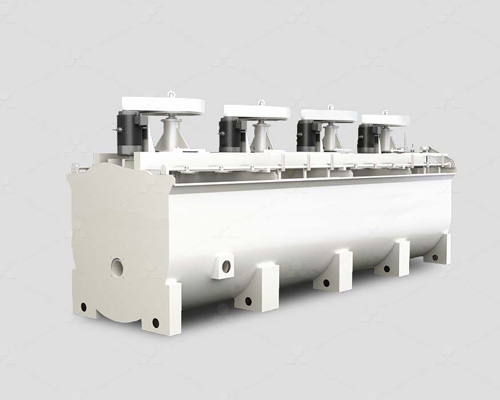

Flotation Machinery

Flotation machinery remains indispensable in resource recovery and environmental management, combining cutting-edge technology with operational reliability to meet diverse industrial demands.Capacity:0.2-38TPH

Application: The machine can be used to separate nonferrous metal, ferrous metal, noble metal, nonmetallic mine, chemical material and recycle mine.

Chat online Call WhatsAppFlotation machinery, also known as flotation cells or flotation machines, is a critical equipment used in mineral processing and wastewater treatment industries. Its primary function is to separate valuable minerals or particles from ores or slurries by exploiting differences in their surface properties. The process involves introducing air bubbles into a slurry, where hydrophobic (water-repellent) particles attach to the bubbles and rise to the surface, forming a froth that is then collected. Hydrophilic (water-attracting) particles remain in the slurry and are discharged. Flotation machinery is widely applied in copper, gold, lead-zinc, and coal processing, as well as in recycling and environmental sectors.

Key Features of Flotation Machinery

- Efficient Separation

- Utilizes advanced hydrodynamic designs to maximize bubble-particle collision and attachment, ensuring high recovery rates and concentrate grades.

- Adjustable parameters (e.g., air inflow, impeller speed) optimize performance for different ore types.

- Modular and Scalable Design

- Available in various sizes and configurations (mechanical, pneumatic, or column flotation cells) to suit small-scale labs or large industrial plants.

- Modular setups allow easy expansion or integration into existing processing lines.

- Robust Material Construction

- Built with wear-resistant materials (e.g., rubber-lined tanks, stainless steel components) to withstand abrasive slurries and corrosive environments.

- Ensures long service life and reduced maintenance costs.

- Energy Efficiency

- Modern designs incorporate energy-saving impellers and optimized airflow systems to minimize power consumption.

- Some models use automated controls to balance energy use and performance.

- Automation and Smart Control

- Equipped with sensors and programmable logic controllers (PLCs) to monitor parameters like pH, slurry density, and froth thickness.

- Enables real-time adjustments for consistent operation and reduced human error.

- Versatility

- Capable of processing a wide range of particle sizes and ore types (e.g., sulfide ores, oxides, coal).

- Adaptable to reverse flotation (removing impurities) or selective flotation (targeting specific minerals).

- Environmental Compatibility

- Reduces waste by recovering valuable materials from low-grade ores.

- Minimizes water usage through closed-loop systems in many applications.

- Low Operational Costs

- Simplified maintenance designs (e.g., easy-access parts, self-aspirating mechanisms) lower downtime.

- High throughput rates enhance overall cost-effectiveness.