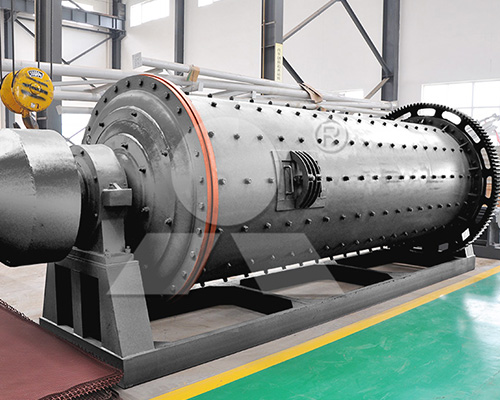

Ball Mil

Ball mills remain a cornerstone in material processing due to their adaptability and reliability across diverse sectors.Capacity:0.65-50TPH

Application: Cement, coal, power plant desulfurization, metallurgy, chemical industry, non-metallic mineral, construction material, ceramics.

Chat online Call WhatsAppBall Mill is a type of grinder used to grind, blend, and sometimes mix materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sintering. It works on the principle of impact and attrition: size reduction is done by impact as the balls drop and collide with the material, and by attrition as the particles slide against each other. Ball mills are cylindrical devices that rotate around a horizontal axis, partially filled with the material to be ground and the grinding medium (e.g., ceramic balls, flint pebbles, or stainless steel balls).

Key Features of Ball Mill

- Versatile Grinding Capability

- Can grind a wide range of materials, including ores, chemicals, ceramics, and pigments.

- Suitable for both wet and dry grinding processes.

- High Efficiency

- Utilizes impact and friction forces to achieve fine particle size reduction.

- Adjustable rotation speed and grinding time to optimize output.

- Simple Structure & Easy Operation

- Comprises a hollow cylindrical shell rotating on its axis, driven by gears or belts.

- Low technical complexity for installation and maintenance.

- Scalability

- Available in various sizes, from laboratory-scale mills to large industrial units.

- Customizable Grinding Media

- Choice of grinding balls (material, size, and density) can be tailored to specific applications.

- Closed-System Design

- Prevents contamination and dust release, ensuring safe operation in sensitive environments.

- Cost-Effective

- Low energy consumption compared to other grinding methods, depending on material hardness and operational settings.

- Durability

- Constructed with wear-resistant materials (e.g., manganese steel liners) to withstand abrasive materials.

Applications

Commonly used in industries such as:

- Mining (ore processing)

- Cement production

- Pharmaceuticals

- Paints and coatings

- Ceramics and glass manufacturing